Testing the technology: How do temperature sensitive foodstuffs react to Aircell technology? Can Aircell save the inevitable salad wilt?

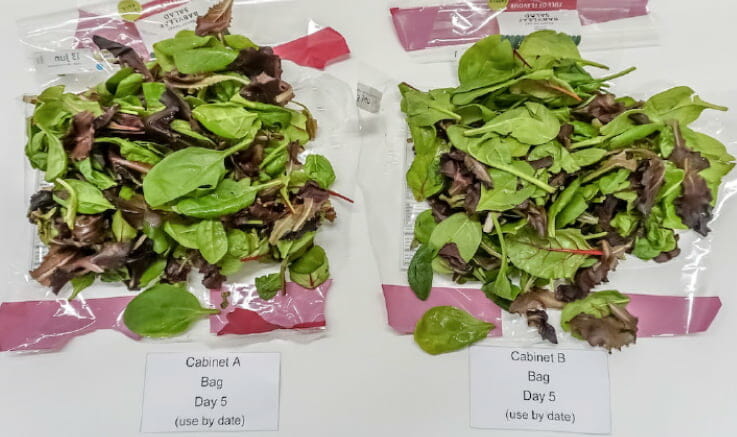

Let’s see how a common foodstuff such as salad leaves fare in a Sarma open-display refrigerated cabinet, powered by Aircell, compared to a standard open cabinet without this new revolutionary technology.

Trials were conducted by Adande and Natures Way Foods, under the guidance of food quality professional David Vagg of AQS. The objective being to assess the impact of the Aircell unit on highly temperature sensitive products, such as, in this case, baby leaf salad.

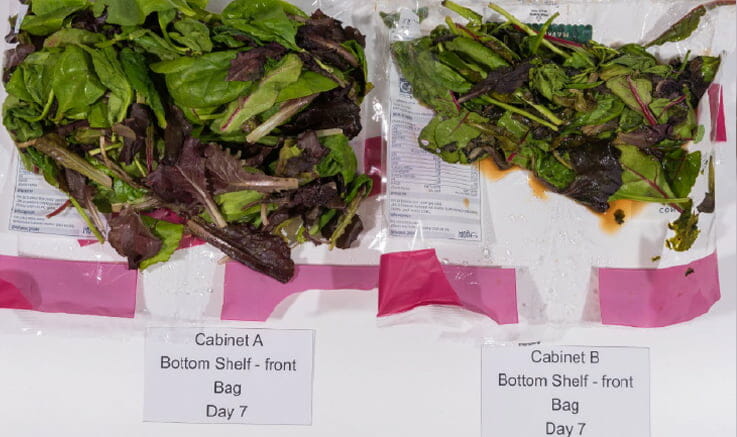

The trials gave a very clear result. Both from product quality parameters (organoleptic) qualities and microbiological assessment. The open Adande Sarma cabinet powered by Aircell, significantly out-performed the traditional open refrigeration unit.

The testing showed :

• The Aircell maintained a tighter air temperature range in all areas of the unit compared to the traditional unit.

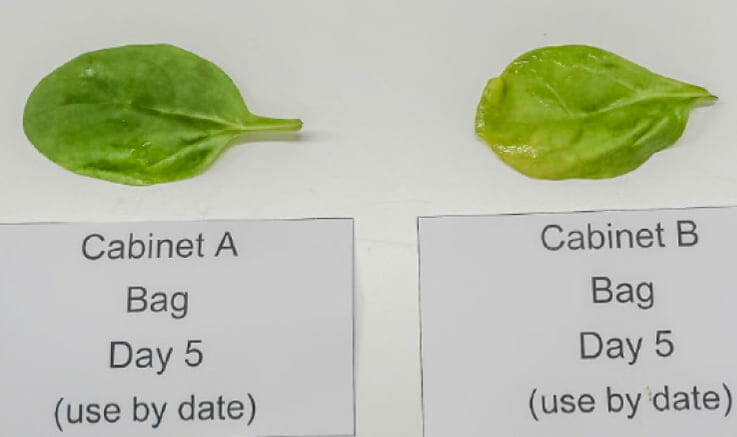

• Product stored in the Aircell unit maintained better Quality condition – organoleptic and physically at the end of shelf life than the traditional unit.

• Product stored in the Aircell unit maintained condition past the Use By date – both organoleptically and physical condition.

• Product stored in the Aircell maintained lower microbiological loading between 10ᶦ and 10² lower over the course of the assessment – the rate of spoilage was slower.

Traditional refrigeration has a broad temperature range across each of the shelves and from front to back. This results in a wide range in product temperatures – freezing products at the back and higher temperatures at the front.

The Aircell ability to maintain a tighter temperature range delivers consistent quality at the end of shelf life – helping ensure food reaches it’s shelf life in the best condition. This directly helps to reduce FOOD WASTE – As there is less product damage caused by freezing and improved end of life quality. The tighter control of the temperature range also means there is scope for shelf-life extension – improving product availability and reducing costs.

Yeasts and Moulds are the major spoilage organism of plant material. The microbiological results show that tighter control of the air and product temperature inhibit the rate of growth of these organisms – reducing the rate at which product quality deteriorates – delivering better product quality for longer.

Improved quality throughout the shelf life of the product also helps improve customer satisfaction and reduce customer complaints due to spoilage and temperature abuse issues arising from widely variable temperature control

A more detailed report of the trials is available on request.

David Vagg Director,

Assured Quality Solutions Ltd.

David Vagg has worked in the food sector for over 30 years. With a key focus on fresh and chilled ingredients he has in-depth knowledge of the organoleptic, quality and safety parameters for a wide range of fresh and chilled ingredients. Assured Quality Solutions Ltd is a food quality, safety and innovation consultancy.