Technology

Aircell explained

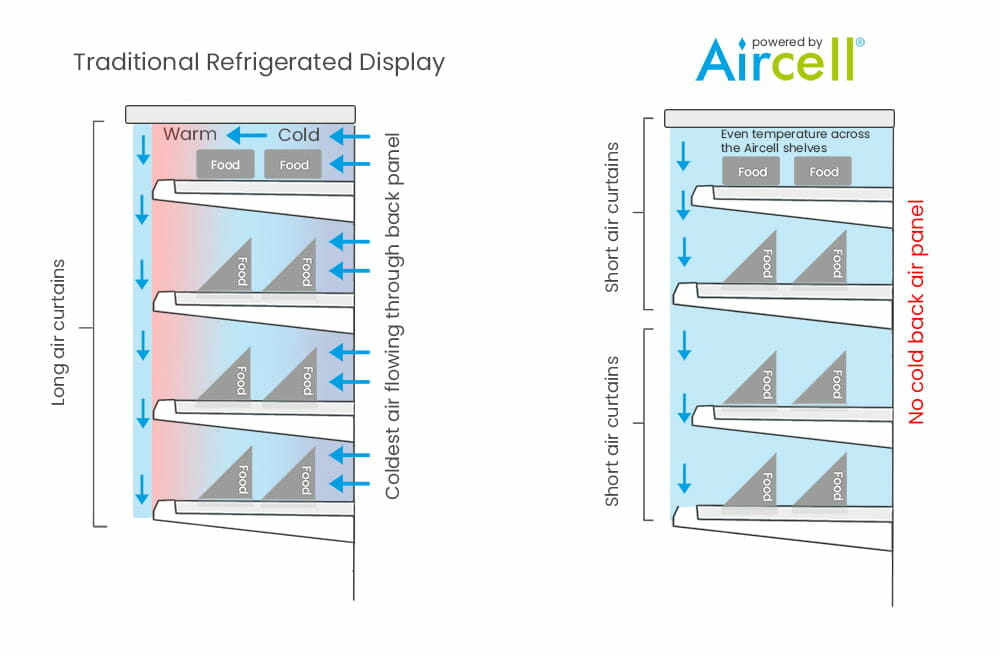

The patented Aircell design replaces the traditional single air curtain with several short air curtains to divide the merchandising area into separate horizontal “aircells”. Cold air is channelled through guide vanes fitted within the Aircell shelf before dropping a short distance from the underside of the front edge of the shelf to be collected by the Aircell shelf below.

Aircell’s proprietary guide vanes are critical to the performance of the cabinet as they distribute the cold air evenly across the full shelf width to ensure that a strong and effective air curtain is maintained.

The short air curtains produced by the Aircell shelves are robust and are not distorted by changes in ambient air temperature or air turbulence in front of the unit. Importantly, and in contrast to other designs cold air does not need to be introduced through the back panel.

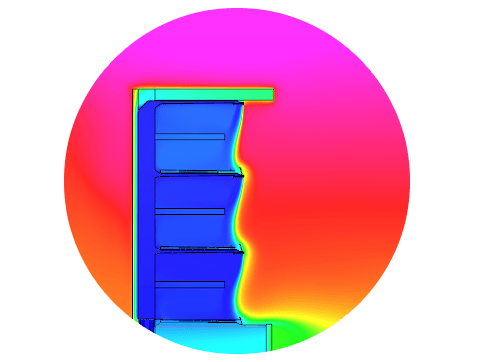

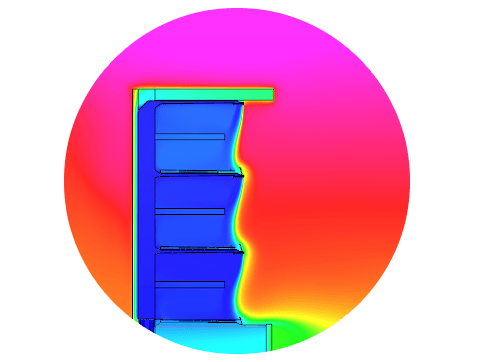

Left: Image shows cold air inside a cabinet powered by Aircell and the consistent temperature that is maintained throughout.

Above: Image shows cold air inside a cabinet powered by Aircell and the consistent temperature that is maintained throughout.

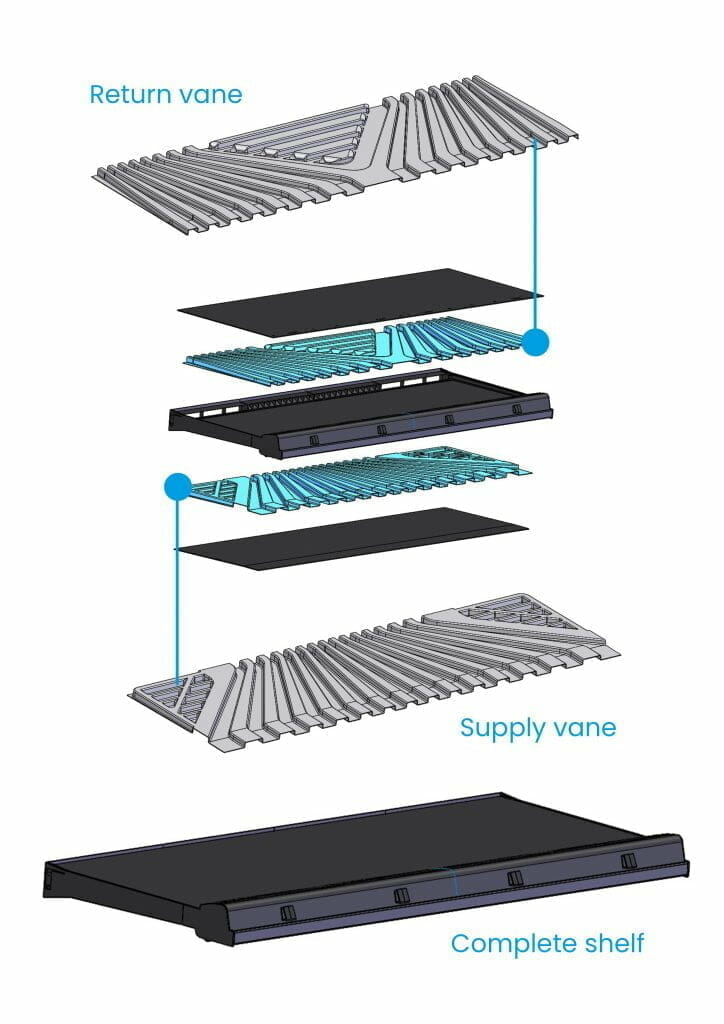

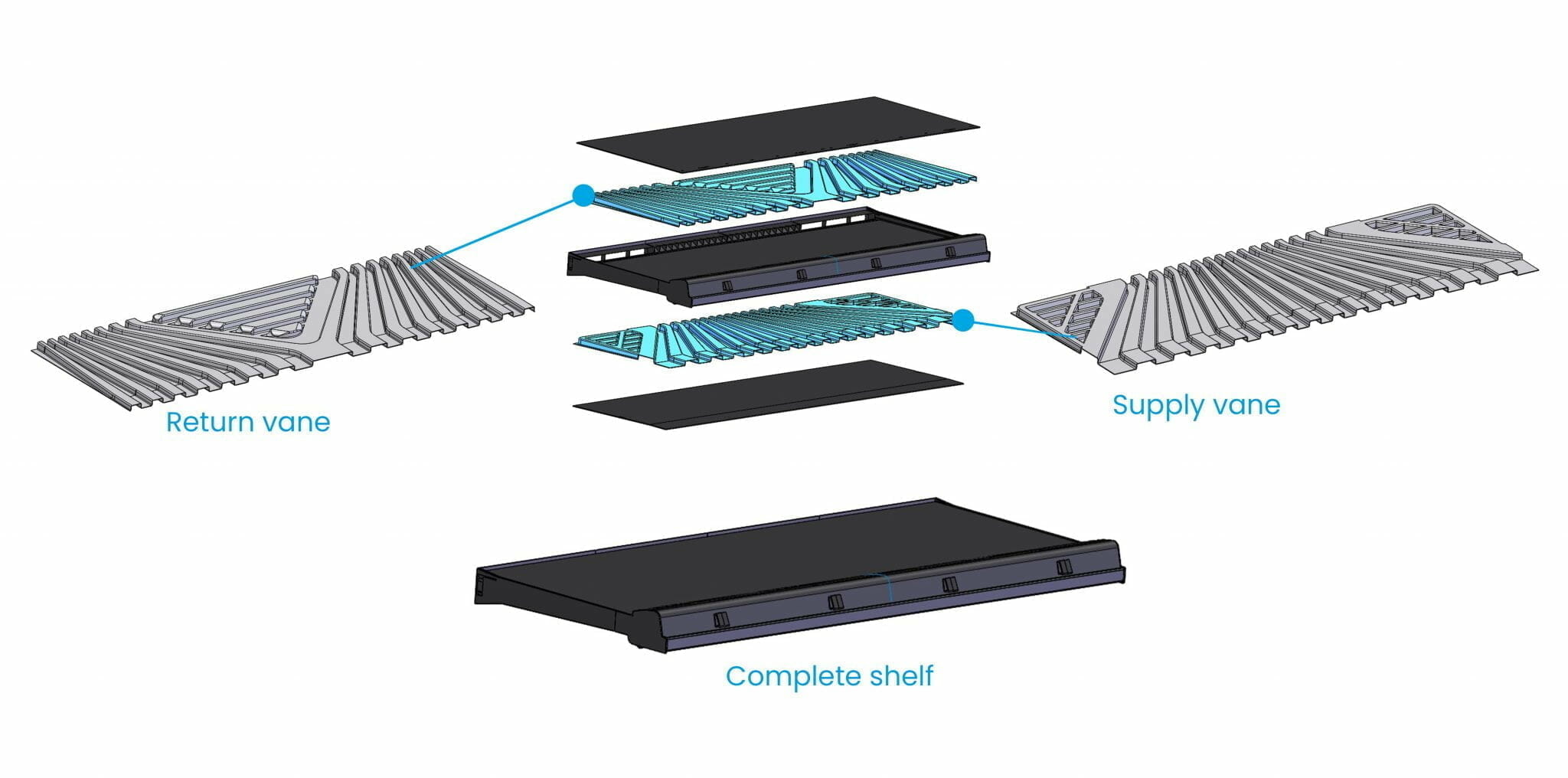

Proprietary shelf design

The shelf design which is integral to the performance of cabinets powered by Aircell is covered by three International patents. Further applications for National and International patents are pending.

The guide vanes enclosed in the shelves manage the cold air supply from, and the warm air return to, the rear wall ducts. The vanes have been designed to ensure there is a very even airflow in the short air curtain across the full width of the shelf. The geometry of both the vanes and the shelf openings have been designed through extensive CFD modelling to guarantee the performance of the shelf sets.

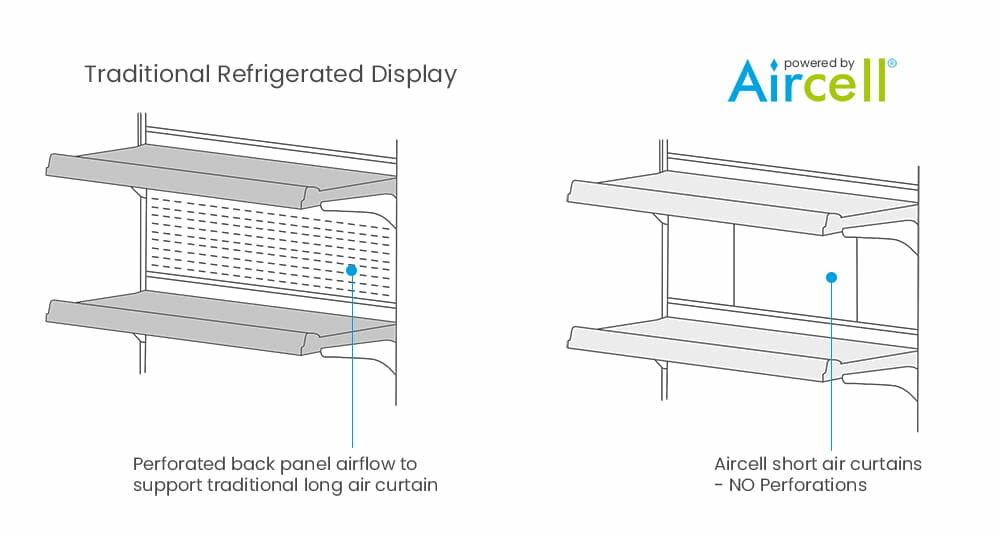

Aircell technology is fundamentally different

Aircell technology delivers a unique way of chilling and preserving food in retail cabinets. See the illustrations above, comparing a cabinet powered by Aircell against a traditional cabinet.

The image on above is a section of shelving from a traditional cabinet, it has a perforated back panel to allow air to pass through, when compared to the image on the right, this is a section of shelving from a cabinet powered by Aircell. You can see there are no perforations here, and no air passes through.

This next illustration shows how the airflows and temperatures differ.

Aircell technology provides a different “experience” for displayed food

Stronger air curtains and no back panel flow means consistent temperature and humidity across the cabinet.

Above is a traditional cabinet with a long curtain of cold air from the top to the bottom. It is a weak barrier and requires cold air to flow through the back panel to keep it pushed out into the right place. That air from the back panel is the coldest air in the system and can be at, or close to, freezing.

However, because the air curtain is weak it gets broken quite easily and often as a result of the shopper reaching across it to select their items. This causes the warmer air in the store, with its associated humidity, to enter the shelves.

The net result is a temperature difference from back to front (very cold to warmer) and across the cabinet because of the instability. Changes in product loading on the shelves causes more instability.

On the right is a cabinet powered by Aircell. There is no back panel flow. The short air curtains (that run between alternate shelves) are robust and withstand the breaching as shoppers take products. The net result is an even temperature and humidity across the cabinet.

This provides a far better experience of food as changes in temperature and humidity impact food quality. While the time on a shelf may be limited, many foodstuffs will show an impact at the store or when the consumer has the product at home. Food products do not recover.

Note that back panel flow is needed for shelves with aerofoils and cabinets with doors.

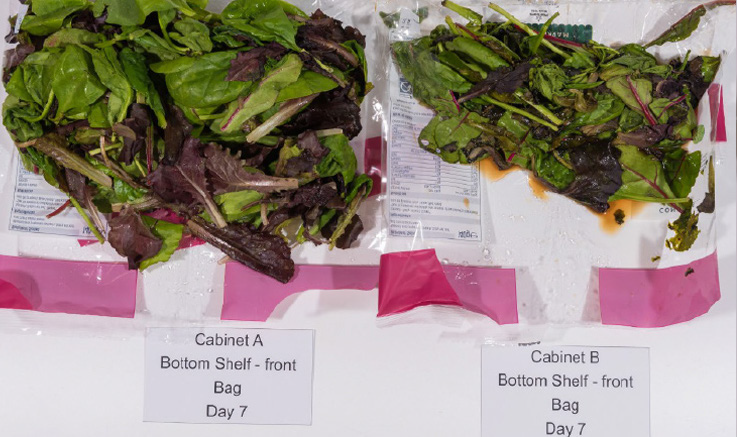

Using Aircell will stop product freezing at the back of shelves, limit dehydration, slow degradation and slow down customer deselection.

Putting Aircell technology to the test

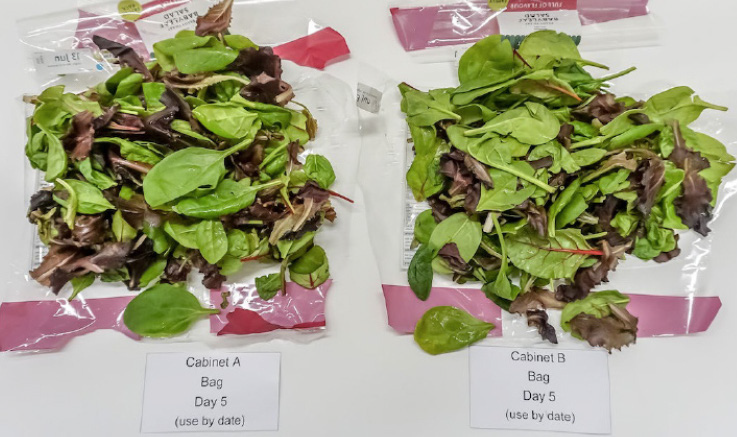

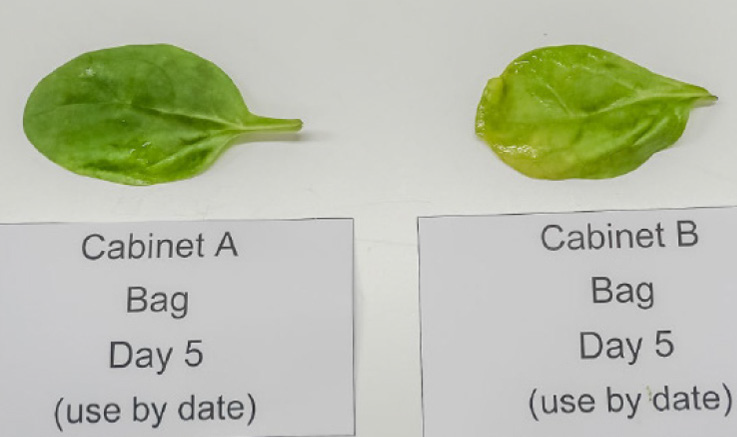

Testing has shown that cabinets powered by Aircell will extend food freshness. Third party validated tests completed on cut salad leaves and various grape varieties have shown that Aircell technology will extend the life of food throughout the cabinet. Below you’ll see a comparison of produce that has been kept in 2 cabinets for 5 days. Cabinet A is powered by Aircell technology and cabinet B is a standard open cabinet.